Cremation Ink Process

At Engrave Ink™, we use a scientifically developed, medically sterile process to transform cremated remains into high-quality commemorative tattoo ink, specifically formulated for cremation tattoos. Whether the ashes come from traditional flame cremation or alkaline hydrolysis (aqua cremation), our process is specifically designed to handle both with the same level of care, safety, and precision.

This page offers a detailed look at how we prepare cremated ashes for integration into tattoo ink (commonly referred to as a tattoo with ashes), and answers some of the most common questions we receive about the science behind it.

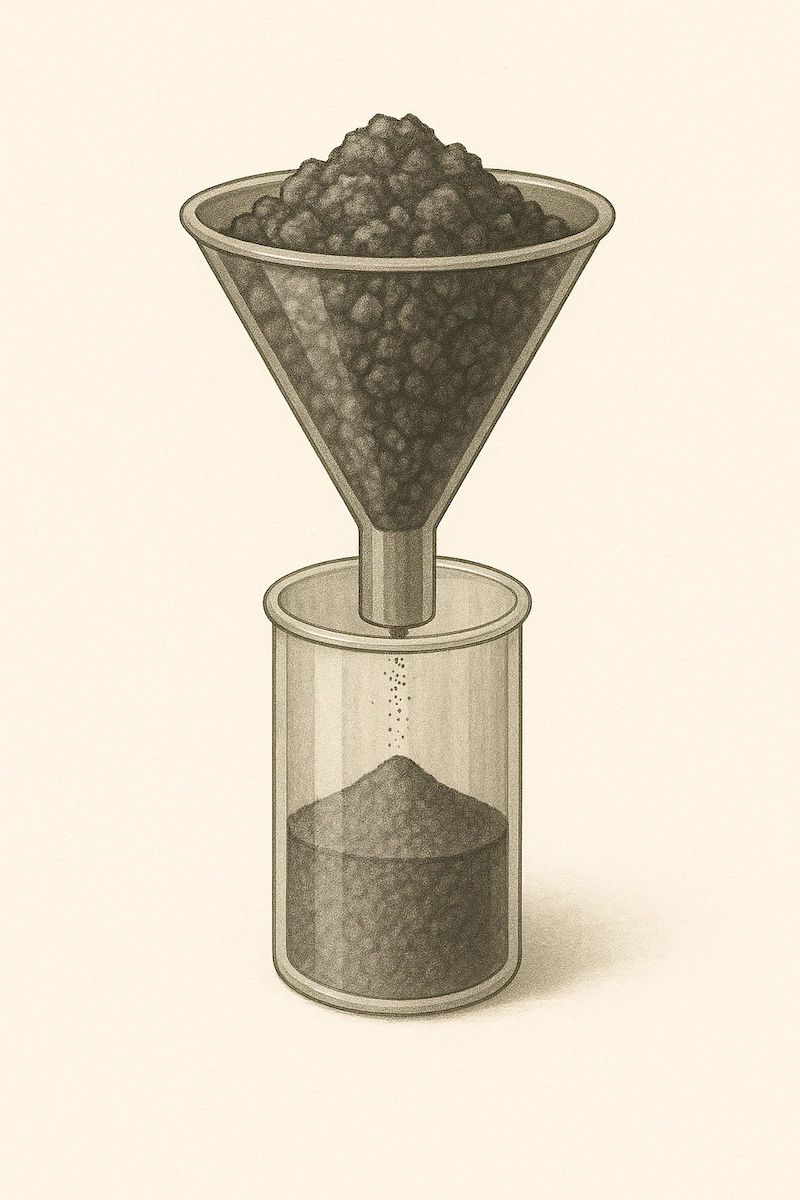

1. Initial Pre-filtration

Before thermal processing, we perform a light pre-filtration step to remove large debris or unprocessed fragments, especially from flame cremation ashes. This ensures safe, efficient handling before high-temperature treatment.

2. High-Temperature Pyrolysis

All ashes, regardless of cremation type, undergo graphite-based pyrolysis in a medically sterile, oxygen-controlled chamber.

At over 2,800°F, this step:

Sterilizes the ashes completely

Refines trace minerals or residual organic content

Produces a chemically stable carbon structure suitable for skin-safe ink

Pyrolysis is a vital step in our process for all cremation types, as it ensures complete sterilization, thermal refinement, and a consistent carbon foundation.

For traditional flame cremation ashes, pyrolysis purifies the naturally present carbon and eliminates residual organic matter, ensuring uniformity and safety.

For alkaline hydrolysis ashes, which contain virtually no carbon and are composed mostly of inorganic bone minerals, pyrolysis enables us to thermally convert trace mineral content into a symbolic, usable carbon structure, making these remains fully compatible with our ink process.

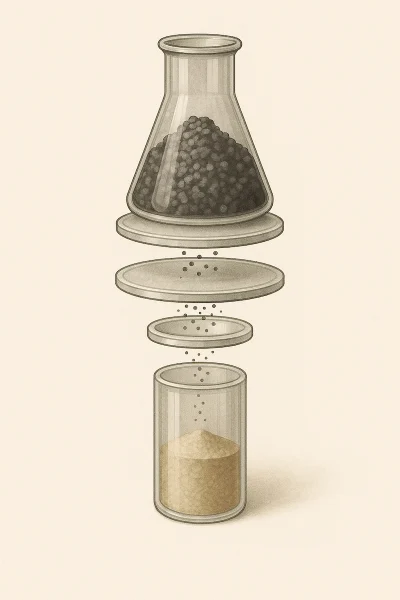

3. Three-Stage Filtration

Following pyrolysis, the ashes are passed through a three-stage filtration system:

-

Two stages of pre-filtration remove coarse or fractured particles.

-

A single microfiltration stage reduces the material to a uniform ~40μm (40 × 10⁻⁶ meters) particle size.

This ultra-fine consistency is critical for smooth blending, long-term ink stability, and safe use in commemorative cremation tattoos.

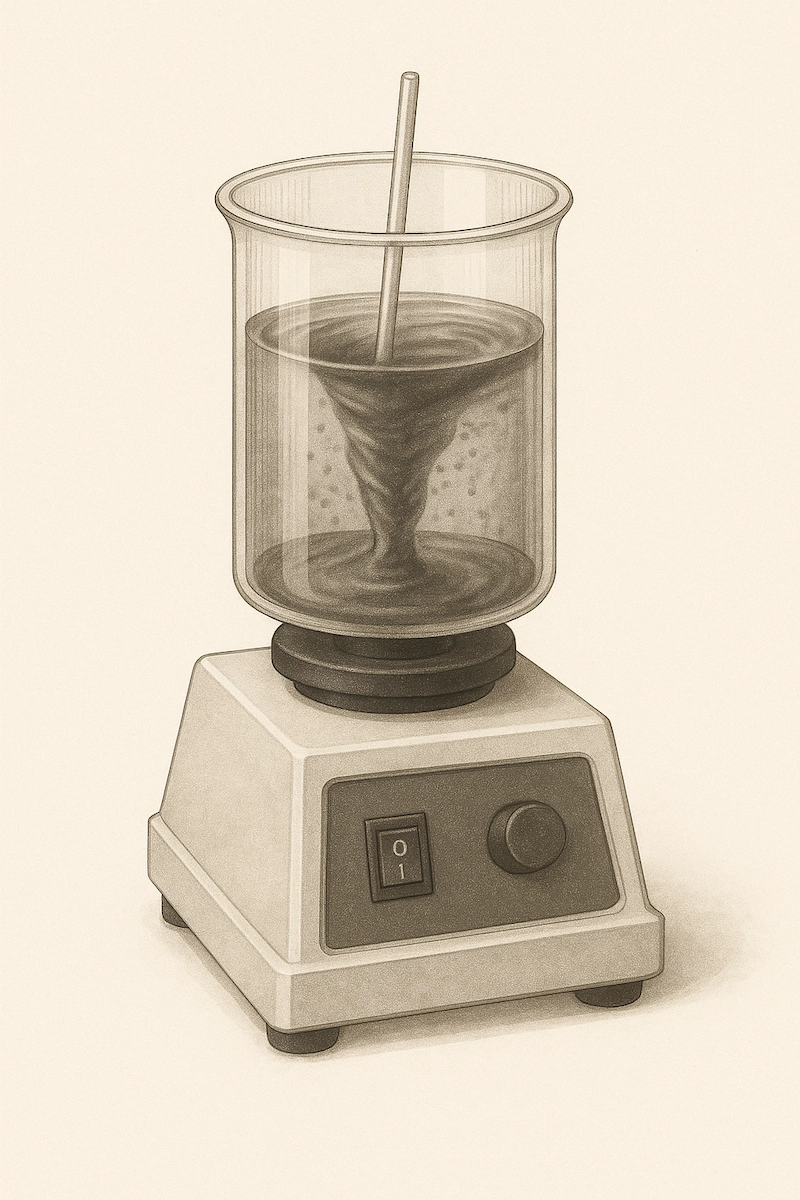

4. Mechanical Agitation

We use lab-grade mechanical agitation to thoroughly blend the refined carbon into our proprietary ink base. This creates a stable, even suspension, resulting in ink that is both symbolically meaningful and professionally formulated.